SOMOS offers specific and ‘Tailor-made’ equipment for each type of problem.

From standard basic elements, SOMOS develops – for each dimension of parts to be treated – 4 series of machines able to satisfy the most diverse surfacing needs (single and/or double face): the most economical equipment ( Cost/performance) to the most powerful machine (“Fine Grinding”), passing through systems intended for specific treatments or mass production under extreme conditions.

This great diversity of machines offered by SOMOS is made possible by the constitution of a set of modules, assembled according to specific needs.

The modules have been gradually and continuously developed using high-performance 3D CAD tools.

Thus, each customer, according to his problem (Dimension, geometry, materials, tolerances, quantities, budgets, etc.) benefits from a wide choice of equipment and processes adapted both technologically and economically.

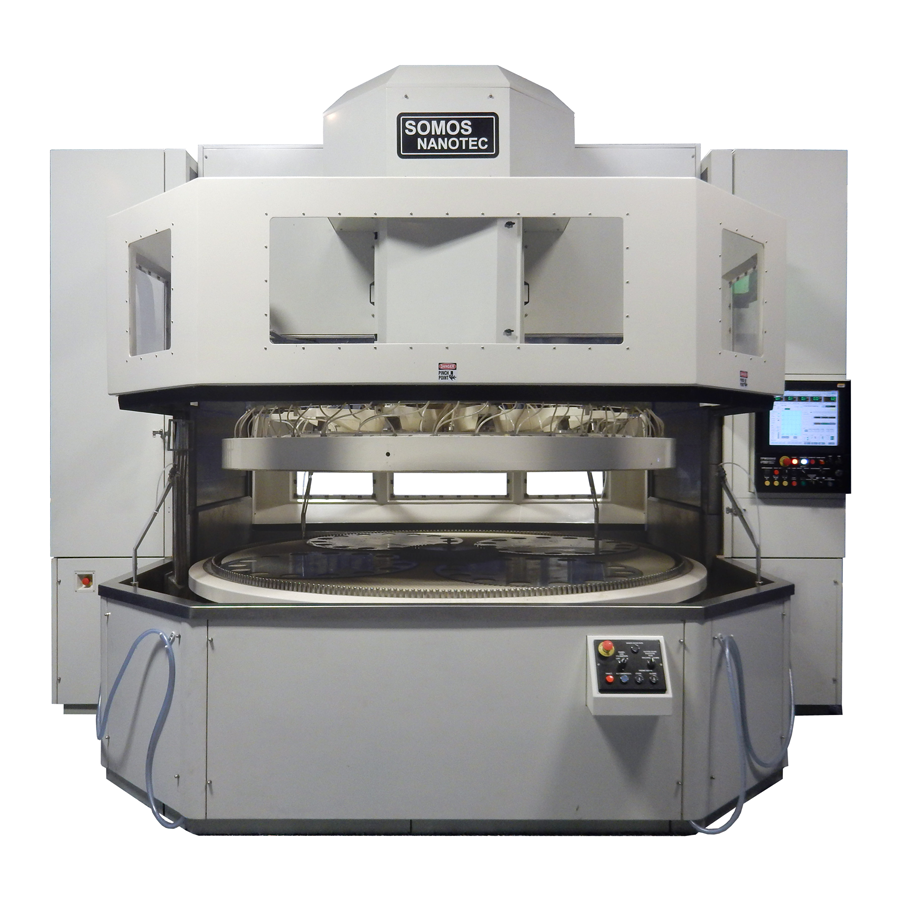

Double Sides Machine “TPM 630A”

Unrivaled since conception, the “Double face” machine has revolutionized the polishing industry by allowing optimal and reliable treatment of parts requiring very tight thickness tolerances, as well as demanding criteria of flatness and parallelism.

Cliquer sur le diaporama ci-dessus

pour voir les références des machines double faces.

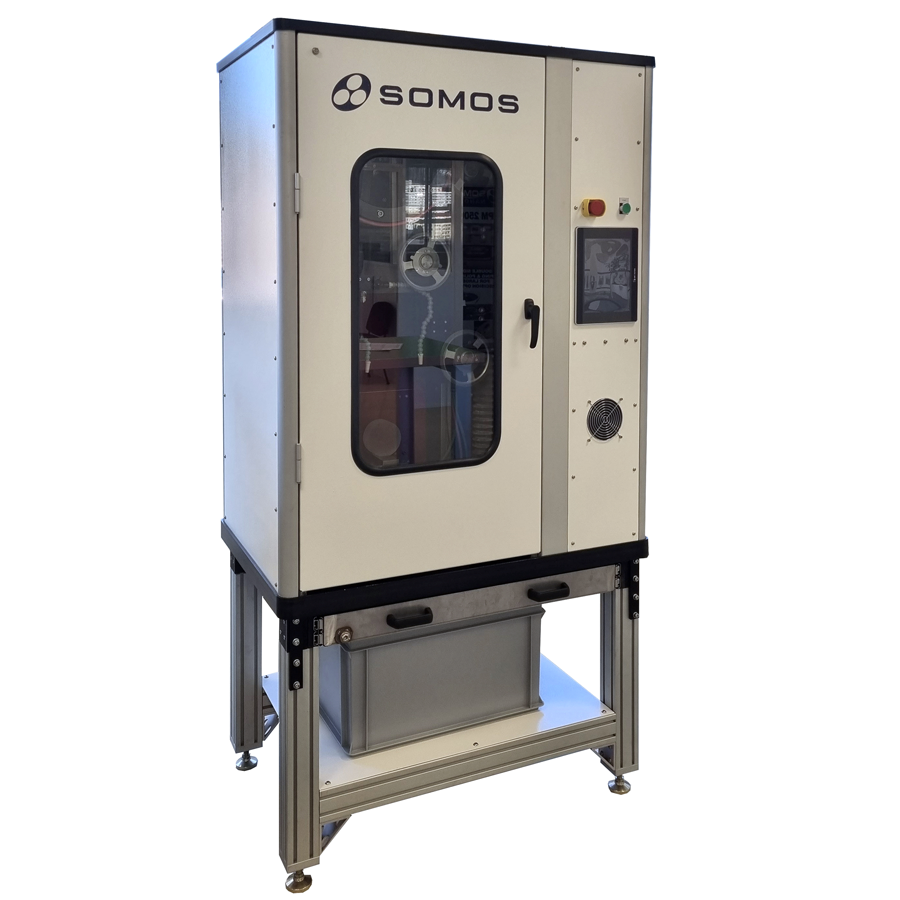

Single-sided machines are widely used in all traditional optical component lapping and polishing operations.

The “Single flat face” equipment (for flat surfaces and large curvatures) and “Single spherical face” (for convex or concave shapes) allow high quality surfacing whatever the geometry of the parts.

Cliquer sur le diaporama ci-dessus

pour voir les références des machines simple face.

Machine simple face “MPR-900”

All production machines benefit from the latest technologies in terms of numerical control and cycle management.

Several types of machines can be integrated into the same process, in order to cover the treatment.

Complete production lines thus allow all operations to be carried out in a fully automated manner.

Cliquer sur le diaporama ci-dessus pour voir les références des lignes de production.

Single Wire Saw

The range of NCSand NCX compact, single-wire saws allow CUTTING, SHAPING and FINISHING CUTTING, at high speed, of the hardest and most fragile materials such as: silicon, silicon carbide, sapphire, quartz, fused silica , CZT, PbTe, BiTe, NdYag, ruby.

Scie à fil “NCS 200”

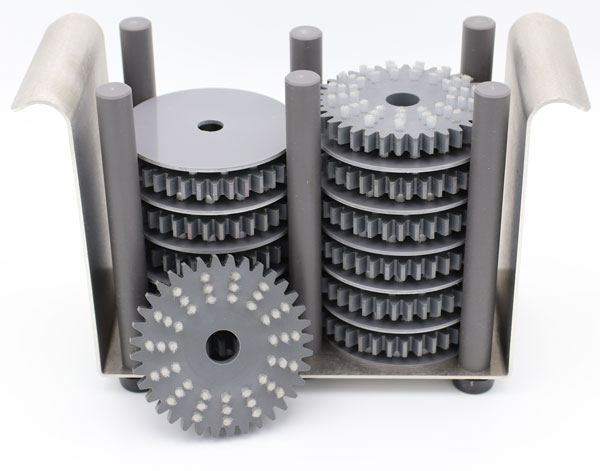

Based on a large database, SOMOS carries out the complete design study and manufacture of specific devices.

Any machine can thus be delivered with its complete set of accessories.

Each machine

can be customized to meet the most diverse needs and for all areas of application.